we have measured almost everything;

from Coat Cupboards to Crime Scenes,

Supermarkets to Super Yachts.

The main issue in almost every situation

is suitable access.

Areas to be measured are often cluttered,

difficult to get to, at height, dirty, or potentially dangerous.

Points can be too far apart, or interrupted by obstructions,

making it difficult to obtain good linear dimensions

Otherwise shapes and layouts can just be too random

to establish a clear detail.

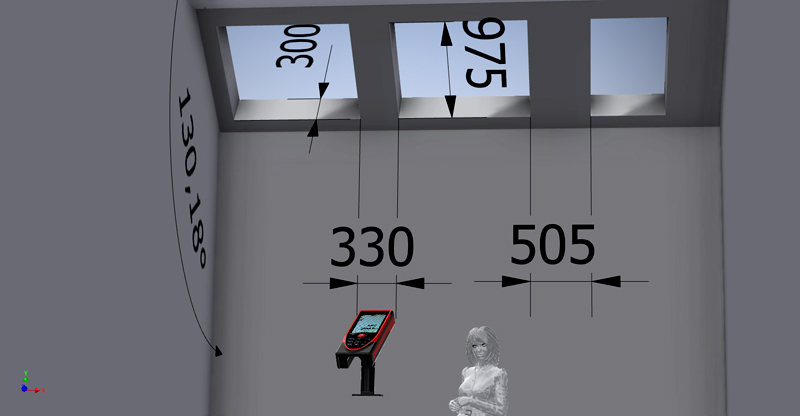

Laser tapes have made surveys significantly easier

but you still need to get to a point to measure from.

In 2017 2TA invested heavily in survey equipment

purchasing a, state of the art, Lieca survey system.

This system provides significant advantages including:-

Measure between points remotely

Measure between points in 3D space

Generate 3D point cloud DXF files

Write 3D surveys directly to AutoCAD

and safety advantages,

of not needing to get to a point to measure it,

this can also provide economies of time,

or allow time to take greater detail.

In creating a CAD .dxf file (or writing directly to a laptop)

the system can also store photos of the laser targets for reference.

Aside confirming survey details, the site photos can be

a valuable asset in establishing any rogue points.

As with all technical systems the equipment is not without foibles.

3D surveys require a managed work flow

to obtain the greatest advantages.

While any Company can buy this equipment off the shelf,

without operatives familiar with the system, and

how the results integrate with the development of CAD details,

it could easily become a very expensive paper weight.